“Simple, Smart & Sustainable – The Bioman Bio STP Process”

“Transforming Waste into Clean Water – Naturally & Sustainably”

Overview – The Bioman Bio STP Process

Bioman Bio STP operates on Anaerobic Biodigestion Reactor Technology (ABRT), an advanced and eco-friendly sewage treatment process designed to minimize operational costs and energy consumption. Unlike conventional systems like MBBR (Moving Bed Biofilm Reactor) or SBR (Sequential Batch Reactor), Bioman’s anaerobic treatment eliminates the need for electricity, motors, blowers, and mechanical components.

This multi-stage process ensures consistent, reliable sewage treatment with minimal human intervention and maximum savings.

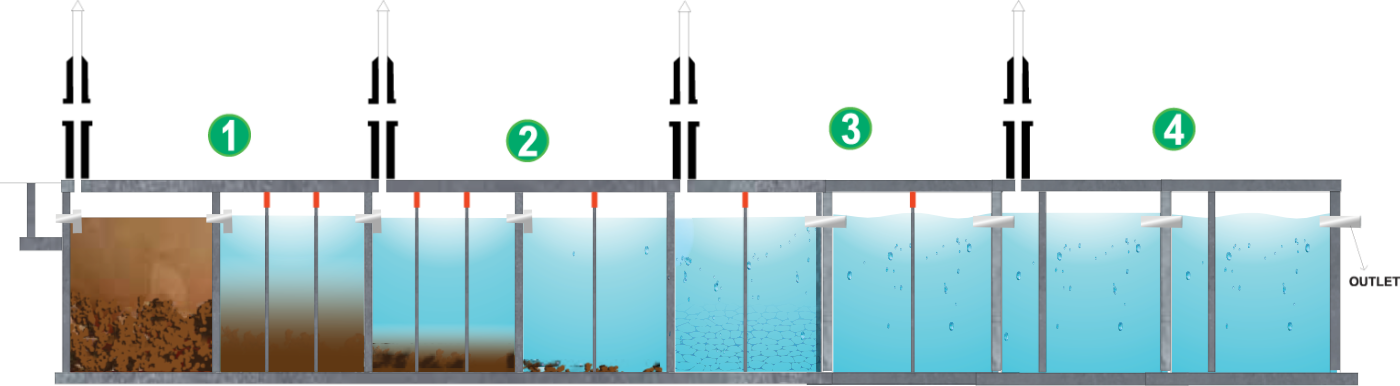

Step-by-Step Breakdown of the Bioman Bio STP Process:

1. Settler / Equalization Tank

The settler is a closed tank consisting of two or three chambers with 16-24 hours of retention time that traps a significant portion of heavier solids and floating particles while letting the rest pass into the following modules.

- Stage: Primary Treatment

- Efficiency: 20-30%

- Maintenance:

- Monthly inspection of wastewater flow

- Monthly removal of scum

- Removal of sludge once in 3-4 years

2. Anaerobic Baffle Reactor

Consists of multiple chambers in series, connected with down-take pipes. The wastewater is made to pass in an up-flow fashion, establishing contact with the sludge blanket at the bottom. The combination of sedimentation and anaerobic sludge digestion ensures the removal of suspended and colloidal particles.

- Stage: Secondary Treatment

- Efficiency: 65-80%

- Maintenance:

- Monthly inspection of wastewater flow

- Desludging every 5 years

3. Biofilm Filter Media

Consists of up-flow chambers connected in series, partially filled with bio-filter media. The biofilm formed on the filter media traps and degrades finer suspended organic particles when wastewater passes through it. Specially designed plastic media is used for better performance.

- Stage: Advanced Secondary Treatment

- Efficiency: 80-90%

- Maintenance:

- Monthly inspection of wastewater flow

- Desludging every 5 years

- Washing of filter media when treatment efficiency reduces

4. Final Collection Tank

A concrete tank with a disinfectant doser is used to kill bacteria, viruses, and other microbes in water. Chlorination is commonly used to prevent the spread of waterborne diseases. Alternatively, ozone can be used as a powerful oxidizing agent, which dissolves in water and acts as a broad-spectrum biocide that destroys all bacteria, viruses, and cysts.

- Stage: Post Treatment

- Efficiency: 90-97%

- Maintenance:

- Periodical filling of chlorine

- Washing of filter media when treatment efficiency reduce

Bioculture – Enhancing Efficiency in Anaerobic Treatment

What is Bioculture?

-

Bioculture is a blend of highly concentrated anaerobic bacteria strains specifically formulated to break down sewage faster and more efficiently.

-

At Bioman, we supply custom bioculture blends depending on site conditions and sewage load.

Benefits of Bioculture:

-

Rapid Start-Up: Reduces the time required to achieve full treatment capacity by 50-70%.

-

Consistent Performance: Maintains high efficiency even during fluctuating sewage loads.

-

Odor Control: Significantly reduces foul odors associated with raw sewage.

🔹 “Ask Us About Our Special Bioculture for Tough Sewage Loads”

Bioman Bio STP vs MBBR vs SBR

| Feature | Bioman Bio STP ( Anaerobic ) | MBBR | SBR |

|---|---|---|---|

| Electricity Consumption | Zero | High – Aeration Blowers Required | High – Batch Blowers and Pumps Required |

| Maintenance Cost | Minimal | Moderate to High | High – Frequent Maintenance |

| Sludge Production | 40-60% Less | High | Moderate |

| Load Capacity Handling | 1% - 100% | 40-100% | 40-100% |

| Operating Cost | ₹0 - ₹10,000/year | ₹1,00,000+ / year | ₹2,00,000+ / year |

| Space Requirement | Compact | Moderate | Large |

| Life Expectancy | 25+ Years | 15-20 Years | 10-15 Years |

| Pollution Control Compliance | Yes (PCB Approved) | Yes | Yes |

| Treated Water Reuse | Yes (Gardening, Flushing, Irrigation) | Yes | Yes |

| Environmental Impact | Low (Zero Carbon Footprint) | Moderate (High Energy Use) | High (Blowers, Pumps, UV Lamps) |

Why Bioman Bio STP is the Future of Sewage Treatment in India

-

Cost Savings: Reduces long-term operational costs by up to ₹1 crore compared to conventional STPs.

-

Simplicity: Fewer components mean less risk of failure and minimal downtime.

-

Eco-Friendly: Contributes to sustainable development by recycling wastewater without chemicals or electricity.

-

Rural and Urban Solutions: Suitable for both remote villages and large metropolitan areas.

🔹 “Experience the Future of Sewage Treatment – Contact Us for a Free Consultation”

🔹 CTA: See the Difference“Schedule a Site Visit to See Bioman in Action”

Step-by-Step Explanation

Collection:

Sewage from buildings is collected into the Bioman BIOSTP unit.

Anaerobic Digestion:

Organic matter is broken down by anaerobic bacteria without the need for oxygen, motors, or blowers.

Filtration:

Solid waste settles at the bottom while clean water rises to the top, ready for reuse.

Reuse:

Treated water can be used for gardening, toilet flushing, and irrigation.

Compliance:

The treated water meets all state and central pollution control norms.

Copyright © 2025 Bioman, All Rights Reserved.